In modern industrial production, the surface treatment of products is crucial. It not only affects the aesthetics of the products, but also directly affects the durability and performance of the products. As an advanced surface treatment equipment, powder coating machines are increasingly favored by all walks of life.

1. Working principle: combination of electrostatic adsorption and high temperature curing

The working principle of powder coating machines is based on electrostatic adsorption and high temperature curing technology. The powder coating is delivered to the spray gun through the powder supply device. The spray gun uses the high voltage generated by the electrostatic generator to charge the sprayed powder particles. At the same time, the workpiece to be sprayed is grounded to form an electrostatic field. Under the action of electrostatic attraction, the charged powder particles are quickly adsorbed to the surface of the workpiece to form a uniform powder coating. This is just like when we rub a comb on our hair to generate static electricity, small pieces of paper will be adsorbed on the comb.

Then, the workpiece with the powder coating is sent to the curing furnace. Under a specific high temperature environment (generally 160 - 220°C), the powder coating begins to melt, level, and undergo a cross-linking and curing reaction, eventually forming a hard, dense coating with various properties, such as corrosion resistance, wear resistance, and weather resistance. The whole process is like putting a layer of solid armor on the workpiece, greatly improving the protective performance and decorative effect of the workpiece.

2. Core components: Collaborative operation to ensure efficient spraying

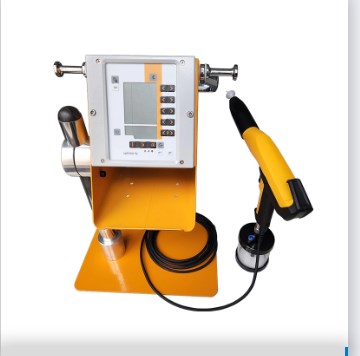

Spray gun: The spray gun is a key component of the powder spraying machine. Its function is to spray the powder coating evenly and accurately onto the surface of the workpiece. The design and performance of the spray gun directly affect the quality of the coating. Modern spray guns usually have adjustable functions, such as powder spraying amount, atomization effect, electrostatic voltage, etc., to adapt to different workpieces and coating requirements. For example, for workpieces with complex shapes, the angle and position of the spray gun can be adjusted to ensure that the powder can evenly cover every corner.

Powder supply device: The powder supply device is responsible for storing and conveying powder coating. It is generally composed of a powder barrel, a fluidizing plate, a powder supply pump, etc. The fluidizing plate fluidizes the powder coating by introducing compressed air, which is similar to the flow of liquid, making it easier to transport. The powder supply pump accurately controls the amount of powder delivered according to the needs of the spray gun to ensure the continuity and stability of the spraying process.

Curing furnace: The curing furnace is the place where the powder coating is cured. It needs to be able to accurately control the temperature and time to ensure that the powder coating can be fully cured. According to different production needs, there are many types of curing furnaces, such as electric heating furnaces, gas heating furnaces, infrared heating furnaces, etc. For example, electric heating furnaces have the advantages of high temperature control accuracy, clean and environmental protection, and are suitable for spraying high-end products with strict temperature requirements; while gas heating furnaces have the advantages of fast heating speed and low cost, and are often used in large-scale production.

Recycling system: The recycling system is an important part of the powder spraying machine to achieve environmental protection and cost savings. During the spraying process, some powder that is not attached to the workpiece will inevitably be generated. The recycling system can collect these powders, filter, separate and other processes, and then send them back to the powder supply device for reuse, which greatly improves the utilization rate of powder coatings and reduces waste and environmental pollution.

3. Wide application: the main force of surface treatment in multiple fields

Automotive industry: In automobile manufacturing, powder spraying machines are used for surface treatment of automobile parts, body frames, etc. Powder coating can not only provide good anti-corrosion performance and extend the service life of automobile parts, but also enhance the appearance of the car through rich colors and textures.

Home appliance industry: The outer shell and internal parts of home appliances such as refrigerators, air conditioners, washing machines, etc. often use powder spraying technology. This not only makes home appliances have a beautiful appearance, but also enhances their scratch resistance and corrosion resistance, and improves the quality and market competitiveness of products.

Construction industry: The surface treatment of building materials such as building doors and windows, curtain walls, and metal pipes is also inseparable from powder spraying machines. Powder coating can give building materials excellent weather resistance, so that they can still maintain good performance and appearance in long-term sun, rain, wind and snow, and can also meet the diverse architectural design needs.

Furniture industry: The metal parts of furniture, such as table and chair legs, handles, etc., can be made decorative and wear-resistant by powder spraying, while meeting environmental protection requirements, providing consumers with healthy and beautiful furniture products.

Fourth, significant advantages: perfect embodiment of environmental protection, high efficiency and high quality

Excellent environmental performance: Powder coating does not contain organic solvents, and will not produce volatile organic compounds (VOCs) during the spraying process, which greatly reduces the pollution to the environment and conforms to the green environmental protection concept advocated by the world. The application of powder recovery system further reduces the waste of powder coating and realizes the effective utilization of resources.

High coating quality: Powder coating has good adhesion, hardness, corrosion resistance and weather resistance. Because the powder particles can be evenly adsorbed to the surface of the workpiece under the action of static electricity, the coating thickness formed is uniform, and it is not easy to have defects such as sagging and bubbles, which can provide long-lasting protection and beautiful appearance for the workpiece.

High production efficiency: The powder spraying machine has a high degree of automation and can achieve continuous production. From workpiece pretreatment to spraying and curing, the entire process can be completed through an automated assembly line, which greatly shortens the production cycle, improves production efficiency, and reduces labor costs.

Powder spraying machines have become an indispensable and important equipment for modern industrial surface treatment with their unique working principle, efficient core components, wide application fields, significant advantages, and good development trends. In the future, powder spraying machines will continue to play an important role in industrial production and contribute to the development of various industries.