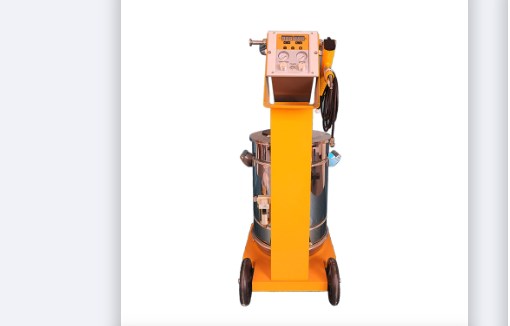

In modern industrial production, surface treatment is a key link to improve product quality and appearance. As the core equipment in the field of surface treatment, powder spraying machine is playing an irreplaceable role in many industries with its unique advantages.

1. Working principle: electrostatic adsorption, precise spraying

Powder spraying machine mainly works based on the principle of electrostatic adsorption. The equipment charges the powder coating through the spray gun. At the same time, the workpiece being sprayed is grounded to form an electric field. Under the action of the electric field force, the charged powder coating quickly moves to the surface of the workpiece and adsorbs tightly, so that a layer of powder coating is evenly covered on the surface of the workpiece. After that, after high-temperature baking, the powder coating solidifies into a film to provide protection and decoration for the workpiece. This electrostatic adsorption method can not only achieve precise spraying, but also greatly improve the utilization rate of powder coating and reduce waste.

II. Significant advantages: environmental protection, high efficiency, and high quality

(I) Pioneer in environmental protection and energy saving

Compared with traditional liquid paint spraying, the powder coating used by the powder spraying machine does not contain organic solvents, which eliminates the emission of volatile organic compounds (VOCs) from the source, and has minimal harm to the environment and the health of operators. Powder coating can be recycled and reused, which greatly reduces the loss of coatings and conforms to the current concept of green development. In terms of energy consumption, the curing process of powder spraying usually adopts efficient heating equipment, with high energy utilization rate, which further achieves the goal of energy saving.

(II) Efficient production tool

The spraying speed of the powder spraying machine is extremely fast, and it can complete the spraying of large areas of workpieces in a short time. Taking the common industrial assembly line as an example, the powder spraying machine can be seamlessly connected with the automated production line to achieve continuous and large-scale production, significantly improving production efficiency. Since the powder coating can achieve a higher thickness in one spraying, the number of spraying is reduced, and production time is also saved.

(III) High-quality coating guarantee

The coating formed by powder spraying has excellent performance. It has strong adhesion and can be firmly attached to the surface of the workpiece and is not easy to fall off; the coating thickness is uniform, which can effectively avoid sagging, leaking and other phenomena, ensuring the flatness and beauty of the coating; moreover, the powder coating has good wear resistance, corrosion resistance and weather resistance, which can greatly extend the service life of the workpiece and improve product quality.

III. Wide application: the common choice of many industries

(I) Automobile manufacturing industry

In the automotive field, powder spraying machines are widely used in the surface treatment of automotive parts, such as wheels, bumpers, frames, etc. The durable, rust-proof and beautiful coating it provides not only improves the performance of automotive parts, but also adds a lot to the overall appearance of the car, meeting consumers' high requirements for car quality and appearance.

(II) Furniture and home industry

Whether it is metal office desks and chairs or metal accessories of wooden furniture, powder spraying machines can show their skills. It gives the surface of furniture a rich variety of colors and textures, enhances the decorativeness and durability of furniture, and at the same time ensures the health and environmental protection of the home environment.

(III) Construction and building materials industry

Building materials such as doors and windows, guardrails, and steel structures are exposed to the outdoors for a long time and need to have good protective properties. Powder spraying machines provide building materials with strong weather resistance and corrosion resistance through high-quality coatings, effectively resisting wind, sun, rain, and frost, extending the service life of building materials, and also adding beauty to buildings.

(IV) Electronic and electrical industry

In the production of electronic and electrical products, powder spraying machines are used for surface treatment of equipment housings and parts. It can not only ensure the exquisite appearance of the product, but also provide good insulation protection for electronic components, ensuring the safe and stable operation of electronic and electrical products.

IV. Industry development: technological innovation, broad prospects

With the continuous advancement of science and technology, the powder spraying machine industry is also continuing to innovate and develop. On the one hand, equipment manufacturers continue to develop new spray guns, intelligent control systems, etc., to further improve the accuracy, efficiency and stability of powder spraying. On the other hand, the types of powder coatings are also becoming increasingly rich, and high-performance and multifunctional powder coatings are constantly emerging, such as coatings with special functions such as self-cleaning, antibacterial, and heat insulation, which have opened up a broader application space for powder spraying technology.

Looking to the future, as the world's environmental protection requirements become increasingly stringent and various industries continue to pursue product quality, powder spraying machines, as an efficient, environmentally friendly and high-quality surface treatment equipment, will surely be widely used in more fields and usher in a more brilliant development prospect.